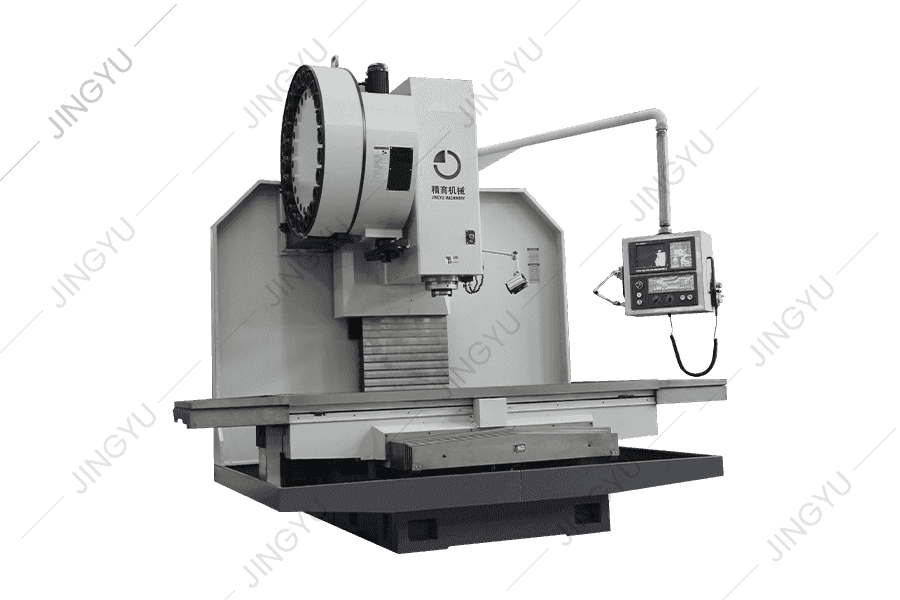

Cat:CNC Roll Milling Machine

CNC Roll Notching Machine

XK9350 series CNC rebar roll crescent groove milling machine is the upgraded product of XK500 type, which is suitable for processing rolls with diamet...

See DetailsReinforced Machine Tool Bed Design

The bed of a reinforced precision CNC milling machine is typically designed using high-strength cast iron or a higher-strength alloy. An optimized internal rib layout enhances overall rigidity. Finite Element Analysis (FEA) simulations are used to simulate the machine's structural loads, ensuring stability under both cutting forces and its own weight. Furthermore, the bed structure undergoes multiple tempering treatments to reduce internal stresses and prevent deformation during long-term use. This bed structure not only enhances load-bearing capacity but also provides the foundation for high-precision machining.

Optimization of Guideways and Slide Components

Guideway design is particularly critical in reinforced precision CNC milling machines. To enhance durability and smooth movement, wide linear guides or double-roller guides are typically used, offering improved load capacity and impact resistance. Guideway surfaces are also hardened or laminated to reduce friction and extend service life. Preloading of sliding components reduces backlash, ensuring accurate positioning during machining. This optimized design not only improves motion accuracy but also reduces wear during extended operation.

Enhanced Spindle System Stability

The spindles of reinforced precision CNC milling machines typically utilize high-precision rolling bearings or hydrostatic bearings, and a preload design minimizes the effects of thermal expansion on machining accuracy. To enhance the spindle's vibration resistance, some models incorporate internal vibration damping devices or improve stability by optimizing the fit between the spindle taper and the clamping system. Furthermore, the use of a spindle cooling system effectively controls temperature during high-speed operation, preventing precision fluctuations caused by thermal deformation.

Improved Tool Magazine and Tool Changing System

The tool magazine and tool changing mechanism in reinforced precision CNC milling machines have been optimized to enhance tool change reliability and speed. The servo-driven tool magazine enables more precise tool positioning, reducing tool change time and improving production efficiency. Furthermore, the tool magazine's clamping structure is more robust, preventing tools from loosening during high-speed tool changes. To reduce the impact of frequent tool changes, a buffering device is incorporated into the system, ensuring a smoother tool change process.

Comprehensive Protection and Enclosed Structure

To enhance the machine's adaptability in harsh environments, reinforced precision CNC milling machines typically utilize a fully enclosed protective structure, effectively preventing cutting fluid and metal chips from entering internal components and reducing maintenance frequency. This enclosed structure also reduces environmental interference with machine operation, such as humidity and dust, thereby extending the machine's overall service life. Furthermore, the enclosed structure provides sound insulation, maintaining a low noise level during operation.

Control System Rigidity Compensation Design

The CNC system plays a key role in reinforced precision CNC milling machines. Through structural rigidity compensation and thermal deformation compensation technologies, it enables real-time adjustment of machining parameters during operation. This intelligent design enables the machine to maintain high machining accuracy even under varying loads and temperatures. The high degree of integration between the control system and the mechanical structure enhances the overall dynamic performance of the machine.

Enhanced Lubrication and Cooling System Structure

The lubrication system design of reinforced precision CNC milling machines has also been enhanced. A centralized automatic lubrication system ensures adequate lubrication of guideways, lead screws, and other key moving parts during operation, reducing wear and extending service life. The cooling system uses multi-point spraying or internal tool cooling to effectively control the temperature in the cutting area, minimizing the impact of thermal deformation on machining quality.

Major structural reinforcements for enhanced precision CNC milling machines

| Structural Component | Enhancement Features | Function |

|---|---|---|

| Machine Bed | High-strength materials, optimized rib layout, tempering treatment | Improve load-bearing capacity and overall stability |

| Guideways and Sliding Parts | Wide-type guideways, surface treatment, preloading design | Enhance motion accuracy and reduce wear |

| Spindle System | High-precision bearings, preloading design, cooling system | Improve vibration resistance and maintain machining accuracy |

| Tool Magazine and Tool Change System | Servo-driven, buffer devices, robust clamping structure | Increase tool change efficiency and ensure smooth operation |

| Protective and Enclosed Structure | Fully enclosed protection, noise reduction design | Reduce external interference and extend service life |

| Control System | Rigidity compensation, thermal deformation compensation | Maintain machining accuracy under varying conditions |

| Lubrication and Cooling System | Automatic centralized lubrication, multi-point spray cooling | Reduce wear and control temperature in the machining area |