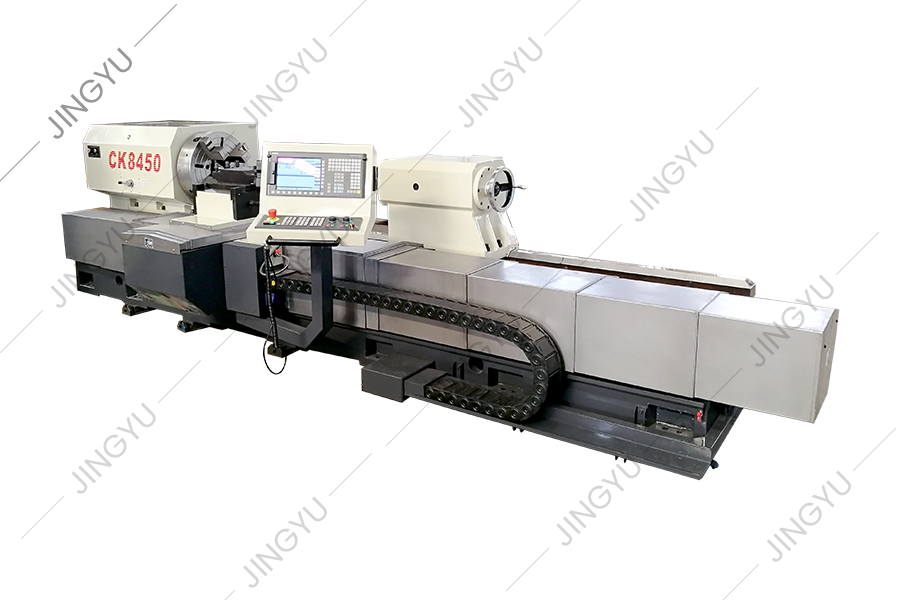

CK8450

●CNC roll lathe bed adopts the overall 4+1 guide rail structure, that is, the bed's horizontal arrangement of four rectangular rails to provide the movement and positioning of the saddle and tailstock, and set up an auxiliary rail on the vertical surface of the front side of the bed for the saddle auxiliary support, so as to ensure that the saddle, the tool holder has a better rigidity, and can bear a greater cutting torque.

●The reference guide rail of the bed adopts the overall super-audio quenching, and the matching surface is affixed with an imported guideway soft belt to ensure the micro-wear movement of each feed component and maintain high precision and high stability for a long time. A certain height difference is designed between the saddle rail and the tailstock rail to ensure that chips and coolant do not invade the saddle rail. The skateboard adopts a rectangular guide rail, which effectively ensures the cutting rigidity and service life.

●The tailstock adopts an independent rotating spindle & axial telescopic adjustment structure of the tailstock sleeve. The tailstock spindle taper hole is MT6#. The tailstock body adopts an integral structure, which eliminates the disadvantages of unstable accuracy, poor load-bearing capacity, and poor reliability caused by the traditional upper and lower split structures.

A butterfly spring is installed in the tailstock spindle to offset the influence of thermal deformation and ensure stability during cutting.

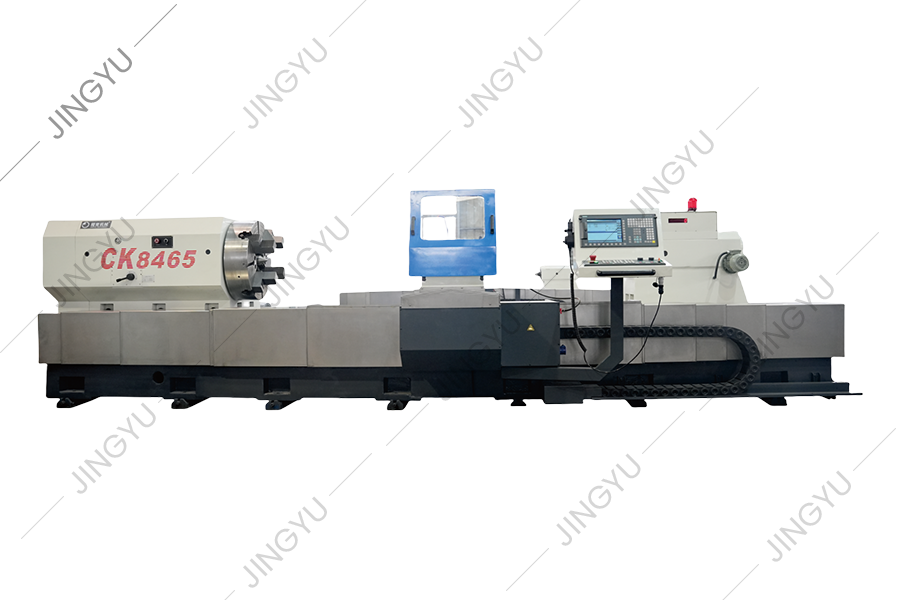

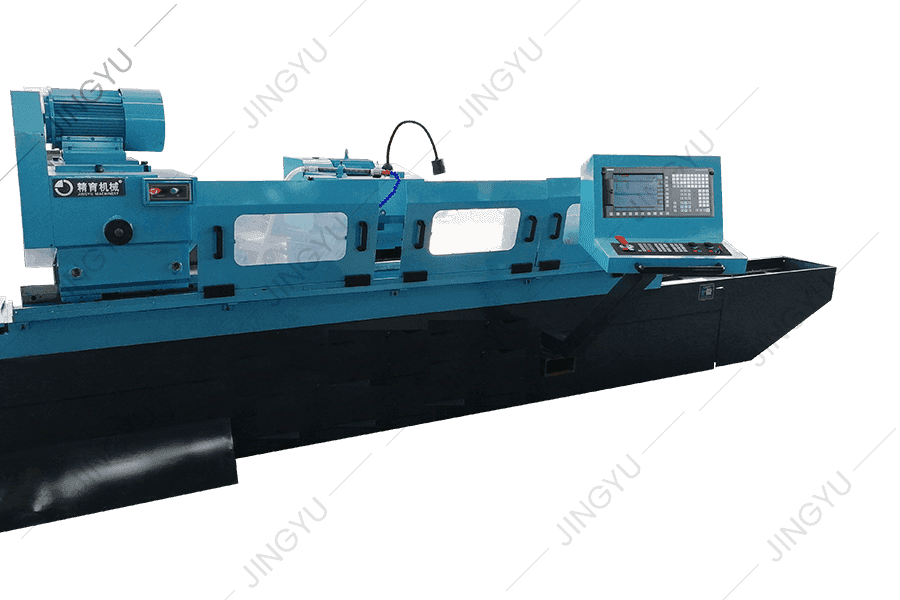

CK8465

●The machine tool adopts the overall 4+1 guide rail structure, that is, the bed horizontal arrangement of four rectangular rails to provide the movement and positioning of the saddle and tailstock, and set up an auxiliary rail on the vertical surface of the front side of the bed for the saddle auxiliary support, so as to ensure that the saddle, the tool holder has a better rigidity, and can bear a greater cutting torque.

●The spindle of the lathe adopts the form of two-point support, and the reasonable bearing configuration and span design make the spindle have higher rigidity and bearing capacity. The optimized transmission system is all driven by 6-level precision gear after high-frequency quenching and grinding so that the headstock has the characteristics of low noise, high transmission accuracy, and large output torque.

The main shaft transmission adopts the stepless speed regulation scheme driven by a 3-gear shift and variable frequency speed regulation motor so that the machine spindle has a wide speed regulation range of 3-240rpm and high dynamic characteristics.

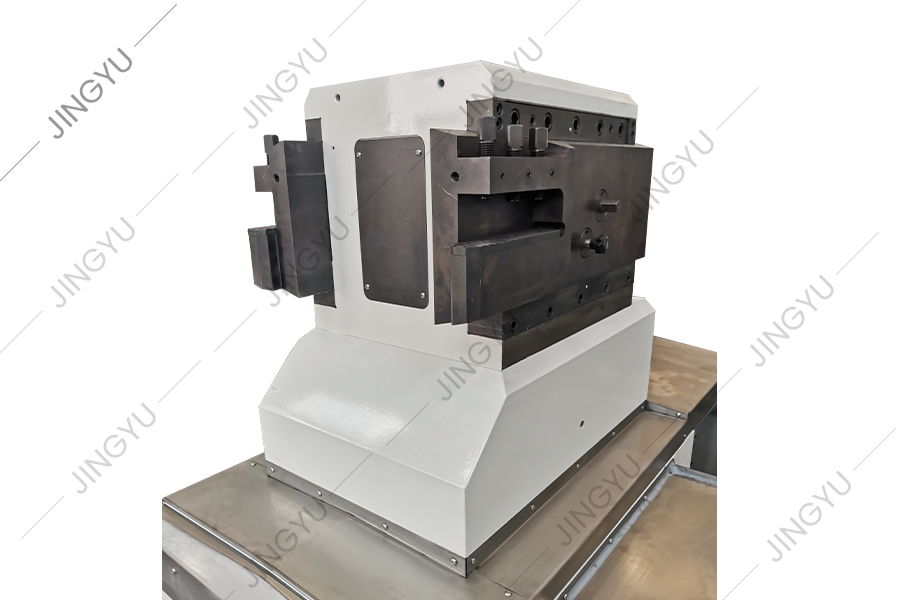

●The saddle tool holder adopts an AO-type integral tool holder scheme. The tool holder can improve the rigidity of the tool holder and reduce the vibration during the turning of the machine tool. And by adjusting the position of the tool holder to adapt to the deep groove pass roll processing. This tool rest solution is very effective on roll lathes from HERKULES in Germany. When the high-hardness roll is turned around, the one-time cutting depth of one side can reach 10mm.

Our company can also choose to configure a CNC tool holder according to the customer's requirements.

●The vertical and horizontal feed of the machine tool adopts a transmission scheme of servo motor, servo motor special reducer, and high-precision ball screw to ensure high torque transmission of the transmission system without forward and reverse backlash, high transmission accuracy, and no hysteresis.

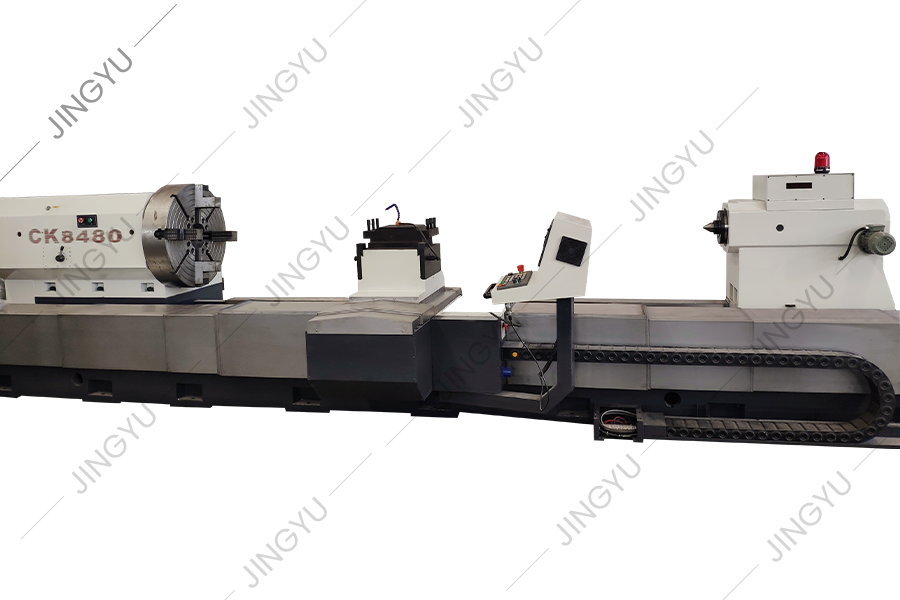

CK8480

●The spindle of the lathe adopts the form of two-point support, and the reasonable bearing configuration and span design make the spindle have higher rigidity and bearing capacity. The optimized transmission system is all driven by 6-level precision gear after high-frequency quenching and grinding so that the headstock has the characteristics of low noise, high transmission accuracy, and large output torque.

The main shaft transmission adopts the stepless speed regulation scheme driven by a 3-gear shift and variable frequency speed regulation motor so that the machine spindle has a wide speed regulation range of 3-240rpm and high dynamic characteristics.

The spindle chuck adopts a heavy-duty chuck and long taper contact, which can transmit greater torque.

●The tailstock adopts an independent rotating spindle & axial telescopic adjustment structure of the tailstock sleeve. The tailstock spindle taper hole is MT6#. The tailstock body adopts an integral structure, which eliminates the disadvantages of unstable accuracy, poor load-bearing capacity, and poor reliability caused by the traditional upper and lower split structures.

The tailstock is equipped with digital detection and alarm display functions for the top pushing force to avoid damage and excessive wear of machine tool bearings and parts caused by unlimited pushing force.

●The vertical and horizontal feed of the machine tool adopts a transmission scheme of servo motor, servo motor special reducer, and high-precision ball screw to ensure high torque transmission of the transmission system without forward and reverse backlash, high transmission accuracy, and no hysteresis.

The guide rail inclined iron adopts a ratchet adjustment mechanism to facilitate later maintenance.

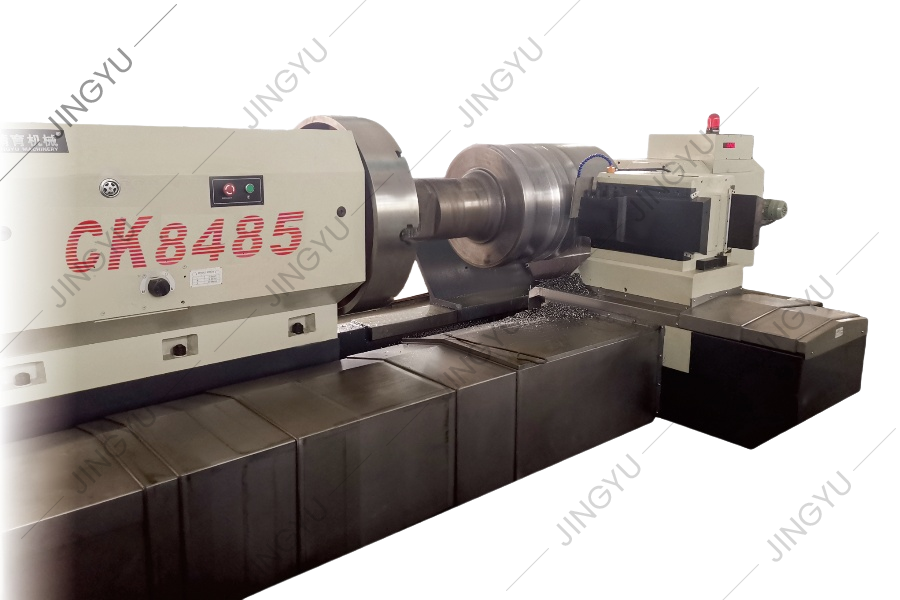

CK8485

●The spindle of the lathe adopts the form of two-point support, and the reasonable bearing configuration and span design make the spindle have higher rigidity and bearing capacity. The optimized transmission system is all driven by 6-level precision gear after high-frequency quenching and grinding so that the headstock has the characteristics of low noise, high transmission accuracy, and large output torque.

The main spindle drive adopts the stepless speed control program of gear shift & DC speed control motor drive, which makes the machine spindle have a wide range of speed control from 3-240rpm with high dynamic characteristics. For the cutting requirements of the large cutting volume of rib removal and repair and billeting rolls, a low gear can be used to ensure the constant torque of the main motor as well as the cutting efficiency. For the finished rolls need high-speed cutting characteristics. High gear can be used, and also can maintain the constant torque of the main motor, to ensure the cutting efficiency.

●The saddle tool holder adopts an AO-type integral tool holder scheme. The tool holder can improve the rigidity of the tool holder and reduce the vibration during the turning of the machine tool. And by adjusting the position of the tool rest plate to adapt to the deep groove pass roll processing. Reduce the lack of rigidity caused by the extension of the tool handle, so that the tool handle resonance, affecting the cutting performance. This tool rest solution is very effective on roll lathes from HERKULES in Germany.

Our company can also choose to configure the CNC tool holder according to the customer's requirements (it is recommended that angle steel users choose).

English

English русский

русский عربى

عربى