Cat:CNC Roll Milling Machine

CNC Notching and Marking Machine

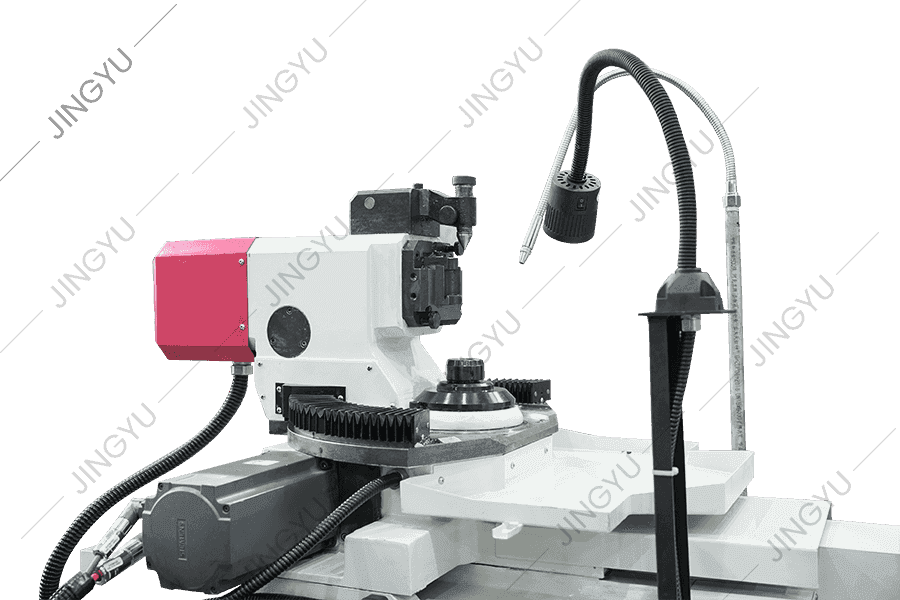

XK9350 series CNC rebar roll crescent groove milling machine is the upgraded product of XK500 type, which is suitable for processing rolls with diamet...

See DetailsAutomatic control technology of CNC roll milling machine

One of the core technologies of CNC roll milling machine is its automated CNC system, which controls the various operations of the machine tool through computer programs to achieve precise control of the roll processing process. Automatic control technology enables the machine tool to work according to the preset processing path and parameters, greatly reducing human operation errors and improving the consistency and stability of processing. At the same time, the CNC system can automatically adjust the tool trajectory and feed speed according to processing needs to ensure the balance of processing efficiency and quality. Through real-time monitoring and feedback adjustment, automatic control technology can also effectively reduce the equipment failure rate and improve the overall operation reliability.

High-precision mechanical transmission system

The CNC roll milling machine is equipped with a high-precision mechanical transmission system, which is a key part to ensure processing accuracy. The high-precision transmission mechanism includes guide rails, lead screws, bearings and other components, all of which use precision manufacturing technology to ensure the smooth and precise movement of the machine tool. The accuracy of the mechanical transmission system directly affects the processing quality and dimensional stability of the roll surface. By optimizing the transmission structure design and using high-quality materials, the CNC roll milling machine can achieve micron-level positioning accuracy, thereby meeting the strict requirements of modern industry for roll processing.

Advanced tool management and cutting technology

CNC roll milling machines use intelligent means in tool management, including automatic tool replacement, life monitoring and intelligent adjustment of cutting parameters. These technologies not only reduce manual intervention and improve processing efficiency, but also extend the service life of tools and reduce processing costs. In terms of cutting technology, CNC milling machines can adjust cutting speed, feed rate and cutting depth according to different roll materials, optimize heat and stress distribution during processing, and avoid roll deformation and surface damage.

Multi-axis linkage and composite processing capabilities

CNC roll milling machines usually have multi-axis linkage functions and can realize complex trajectory processing. Multi-axis linkage technology allows the machine tool to control the movement of multiple axes at the same time, realizing the combination of milling, grinding, drilling and other processing methods. This composite processing capability enables CNC roll milling machines to complete multiple processes in a single clamping, reducing the number of workpiece loading and unloading times, improving processing efficiency, and ensuring the consistency of processing accuracy.

Efficient cooling and chip removal system

When processing rolls, the heat and chips generated by cutting will directly affect the processing quality. The CNC roll milling machine is equipped with an efficient cooling system, which can timely remove the heat from the cutting area, reduce the temperature of the workpiece and the tool, and reduce the risk of thermal deformation. At the same time, the chip removal system is reasonably designed to quickly remove chips, avoid chips from scratching the processing surface and blocking the equipment, keep the processing environment clean, and ensure the normal operation of the machine tool.

Advanced software support and simulation technology

The CNC system of the CNC roll milling machine is equipped with an advanced software support platform, which is not only responsible for programming the processing path, but also for simulating and optimizing the processing process. Through software simulation technology, operators can preview the processing process in advance, find potential problems and adjust processing parameters, reducing the number of trial processing and material waste. The software also supports data collection and analysis, which helps to continuously improve the processing technology and equipment performance.

Human-computer interaction interface design

The CNC roll milling machine adopts a friendly human-computer interaction interface, which is convenient for operators to input programs, set parameters and diagnose faults. The interface design focuses on simplicity and intuitiveness, making the operation process smoother and reducing the difficulty of operation. At the same time, modern human-computer interfaces usually support touch screens and graphic displays, which improves the operating experience and efficiency. Through the interface, the operator can monitor the processing status in real time, respond quickly to abnormal situations, and ensure production safety and processing quality.

Modular design of equipment

The CNC roll milling machine adopts a modular concept in design to facilitate the installation, maintenance and upgrading of the equipment. The modular design allows each component to be disassembled and replaced independently, reducing maintenance time and cost. At the same time, the modular design facilitates functional expansion and personalized customization according to customer needs, improving the adaptability and service life of the equipment.

Environmental protection and energy-saving technology

With the promotion of energy-saving and environmental protection concepts, CNC roll milling machines have also incorporated environmental protection and energy-saving measures into core technologies. By optimizing the machine tool structure and power system, energy consumption and exhaust emissions are reduced. Reasonable energy recovery and control systems reduce resource waste in equipment operation, which meets the requirements of modern industry for green manufacturing.

Safety protection system

In order to ensure the safety of the operator and the stable operation of the equipment, the CNC roll milling machine is equipped with multiple safety protection systems. This includes emergency stop buttons, protective covers, overload protection and abnormal alarm devices. The safety protection system can intervene in time when the equipment is abnormal, prevent accidents, and reduce equipment damage and personnel injury risks.

Comparison of core technologies of CNC roll milling machines:

| Technical Feature | Main Function Description | Impact on Machining |

|---|---|---|

| Automation Control Technology | Computer program controls machining paths and parameters | Improves machining consistency and efficiency |

| High-Precision Mechanical Transmission System | Precision guideways and lead screws ensure accurate machine movement | Ensures machining accuracy and surface quality |

| Tool Management and Cutting Technology | Automatic tool changing and intelligent cutting parameter adjustment | Reduces tool wear and lowers costs |

| Multi-Axis Linkage and Composite Machining Capability | Coordination of multiple axes to complete complex trajectory machining | Enhances machining efficiency and reduces clamping errors |

| Cooling and Chip Removal System | Efficient cooling and chip removal | Maintains machining stability, prevents thermal deformation and equipment blockage |

| Software Support and Simulation Technology | Machining path programming and process simulation | Optimizes process and reduces trial errors |

| Human-Machine Interface Design | Intuitive operation interface with fault diagnosis support | Simplifies operation process and improves safety |

| Modular Design | Components can be independently disassembled and replaced | Lowers maintenance difficulty and facilitates upgrades |

| Environmental Protection and Energy Saving Technology | Structural and power system optimization for energy saving and emission reduction | Reduces operational costs and meets environmental requirements |

| Safety Protection System | Emergency stop, protective covers, overload protection, etc. | Ensures personnel and equipment safety |